1. what is CNC?

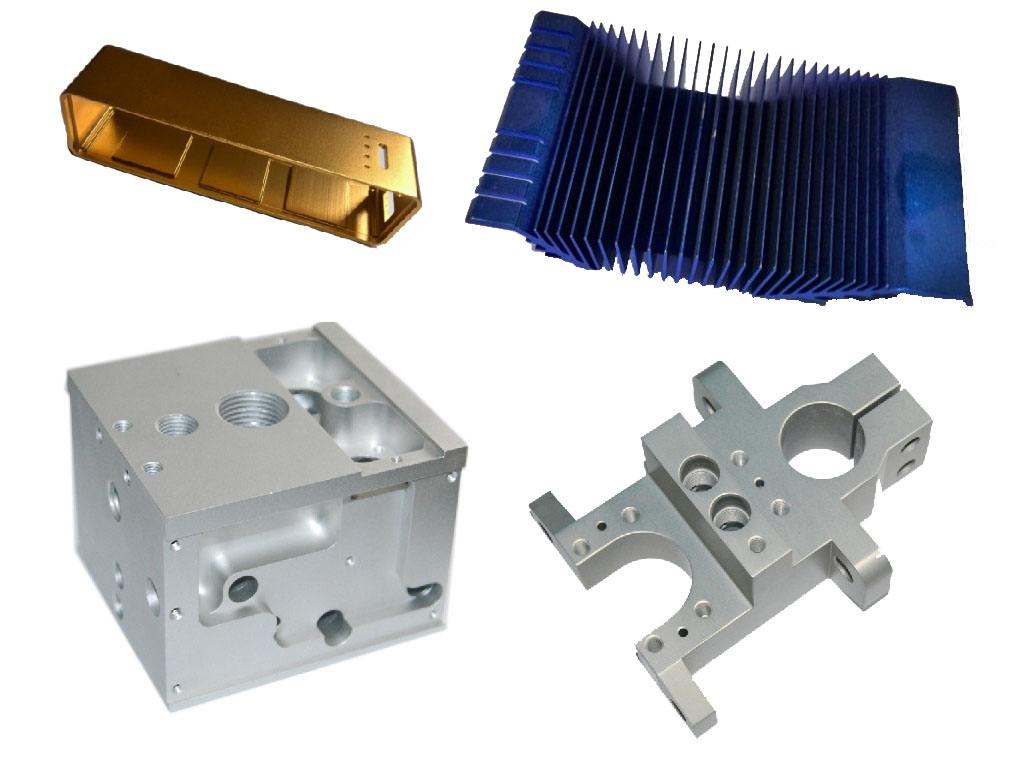

CNC (Numerical Control Machine) is an abbreviation of Computer Numerical Control. It is an automatic machine controlled by a program,which is often used for robot parts CNC machining,such as guide robot parts CNC machining, CNC machining automotive prototype, UAV parts CNC machined, CNC machined 3D Printer Parts, bank equip parts CNC machined and so on.The control system can logically process programs with control codes or other symbolic instructions that can be decoded by a computer to enable the machine to perform the prescribed actions and to machine the stock material into finished product parts by cutting. CNC machine tools can complete a single processing program, you can also complete a variety of machining processes in a machine, such as cars, milling, drilling … … Advanced multi-function CNC machine tools, also known as the machining center, has a very powerful Processing capabilities, many in the past can not be artificially processed shapes can be machined from this machine, just as carving, to make extremely complex products. And fast, high precision. Ordinary machine tools, you need to manually set the machine according to the parts to be machined, adjust the tool bit, the processing range, the amount of processing … and so on parameters, and then manual control, a workpiece may be on a machine Processing several times, may also need to convert several machines to complete the processing.

2.components:

Host, he is the main CNC machine tools, including machine tools, columns, spindle, feed mechanism and other mechanical components. He is used to complete a variety of machining parts of the machinery.

CNC device is the core of CNC machine tools, including hardware (printed circuit board, CRT display, key box, tape reader, etc.) and the corresponding software for the input of digital parts program and complete the input information storage, data Transform, interpolate computation and realize various control functions.

Drive, he is the driving part of the CNC machine tool actuators, including the spindle drive unit, feed unit, spindle motor and feed motor. He drives the spindle and feed via electrical or electrohydraulic servo systems under the control of a numerical control unit. When several feed linkage, you can complete the positioning, straight line, plane curve and space curve processing.

Auxiliary devices, CNC machine tools, some of the necessary supporting components to ensure the operation of CNC machine tools, such as cooling, chip removal, lubrication, lighting, monitoring and so on. It includes hydraulic and pneumatic devices, chip removal devices, exchange tables, CNC turret and CNC indexing head, but also tools and monitoring devices such as detection.

Programming and other ancillary equipment, can be used to machine parts programming, storage and so on.

3. CNC machining features:

- Processing high precision, with high processing quality;

- Multi-coordinate linkage can be processed to shape the complex parts;

3 processing parts change, generally only need to change the NC program, saving production preparation time;

- Machine tool itself, high precision, rigidity, you can choose the amount of favorable processing, high productivity (usually for ordinary machine tools 3 to 5 times);

- High degree of automation of machine tools, can reduce labor intensity;

Batch production, product quality easy to control;

- Its inconvenient maintenance, high technical requirements

- The quality requirements of the operator is lower, the technical requirements for maintenance personnel higher.