Prototyping model and CNC machining is an advanced modern enterprise processing methods. Shouban is the first sample of the product, the early industrial samples are hand-made, so called Shouban. Shouban the four major determinants of the importance of hand model production, the product pre-mold work to lay a certain foundation:

1, test design:

Shouban is not only visible but also touchable. He can intuitively reflect the designer’s ideas and concepts in a physical form, avoiding the disadvantages of “drawing good looks and not looking good”. Therefore, Shouban production in the development of new products, product appearances in the process is essential.

2, test structure design:

Because the hand board can be assembled, so it can intuitively reflect the structure is reasonable or not, the ease of installation. Facilitate the timely detection of problems, solve problems.

3, to avoid the risk of directly open the mold:

As the cost of mold manufacturing are generally high, the larger mold worth hundreds of thousands or even millions, if you open the mold found in the structure of unreasonable or other problems, the loss can be imagined. Shouban production can avoid this loss and reduce the risk of mold.

4, so that products available time greatly ahead of schedule:

Due to the advanced nature of handcraft production, you can use the palm for product promotion and even pre-sales, production and other preparatory work before the mold is developed and capture the market design process as early as possible.

Shouban model produced six main steps:

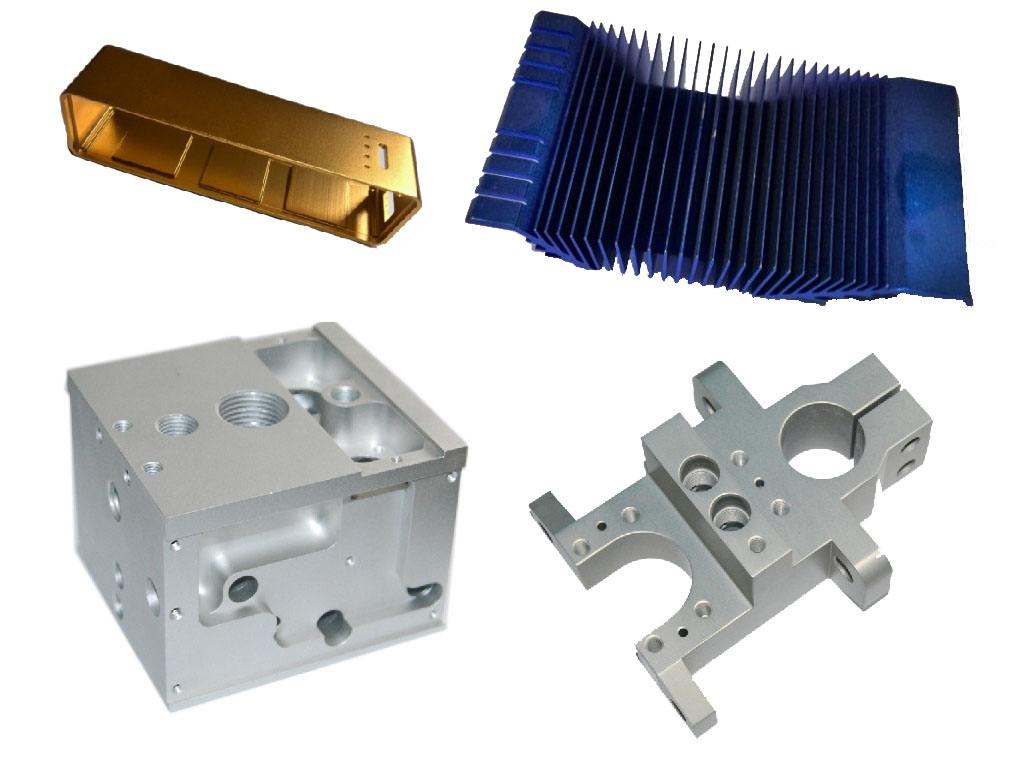

Shouban model is often used in industrial design and production of a mold, most of the current Shouban model used in the production of CNC machining centers to achieve. In the production of the prototype model will go through the following steps:

1, programming. Programming is the first step in hand model making. The programmer analyzes the 3D data of the product and writes the programming language that controls the NC machining center.

2, CNC machining. Is to program language input to the computer, through the program’s command for precise processing.

3, manual processing. After the renovation of the product processing, at the same time the completion of the work of data proofing, as well as the removal of burrs, grinding and other processes, these processes can be handled by hand.

4, surface treatment. Through a variety of ways to achieve different effects inside the surface effect, when dealing with the main painting, plating, in some cases there will be anodizing, drawing and other work.

5, assembly. In dealing with the opponents plate after the need for assembly and data testing, but before the surface treatment, the general assembly is also to be the first to work to ensure the performance of the equipment.

6, packaging. After the completion of the product processing, it is necessary to carry out quality testing, and then packaging the product.

All in all, the importance of making a palm model is that it effectively controls our production costs and takes the lead in the market.