Aluminum parts machining increasingly widespread use,Here are Industrial aluminum oxidation process:

① aluminum surface treatment:

Aluminum surface treatment, also known as surface pretreatment, is the use of physical substances and chemical substances on the surface of the aluminum to remove the dirt so that the exposed aluminum body, for the latter part of the aluminum surface oxidation treatment.

② aluminum surface degreasing process:

Aluminum degreasing process its purpose is to remove the surface of industrial aluminum and anti-corrosion oil and preservative oil attached to the surface of the dirt and impurities attached to ensure uniform corrosion of aluminum profile to ensure that the alkaline etching tank cleaning; improve the quality of aluminum surface treatment.

③ aluminum etching process:

The aluminum surface etching process is after degreasing the surface of the aluminum acid etching, to the main purpose is to remove the oxidation of other metal elements on the surface of the aluminum oxide and profiles after the formation of natural oxide film; acid etching immediately after Water washing, washing temperature control as early as 50 ℃, to avoid flow marks on the profile surface, and then carry out mobile water cleaning. As the aluminum profile contains copper, the surface is dark after the acid has been tried. After 3-5 minutes of bubbling in the nitric acid solution, the surface is bright silver.

④ Alkali etching process:

Alkali etching process, the main purpose of the acid etching process is roughly the same, to remove the aluminum material in the oxidation process of the body surface of the residual material and the metamorphic layer, and eliminate aluminum extrusion surface scratches in the process of defects; aluminum Alkalin surface treatment for the overall quality of the aluminum surface has a crucial role.

⑤ aluminum and the process:

The purpose of the aluminum profile neutralization process is to remove alloying elements or impurities such as copper, manganese, iron, silicon and other insoluble elements in the alkaline solution remaining on the surface of the aluminum profile after the acid etching treatment and the alkali etching treatment, Alkali etching after the remaining lye, under normal circumstances is the use of 30% -50% of nitric acid solution, for high-silicon aluminum alloy, cast into the alloy, the use of nitric acid and hydrofluoro 1: 3 volume ratio of the mixture acid. Silicon and hydrogen and hydrofluoric acid generated fluosilicate and left the aluminum surface.

⑥ aluminum anodizing:

Aluminum anodizing method is through the solution as a medium, the use of cutting-edge discharge so that the aluminum surface layer of oxide film, so that the aluminum has super corrosion resistance, due to anodized aluminum profile obtained by the protective layer Has a high hardness and corrosion resistance, the standard thickness of 10-12μ, can better improve the oxidation resistance of aluminum profiles and improve the appearance of the profile

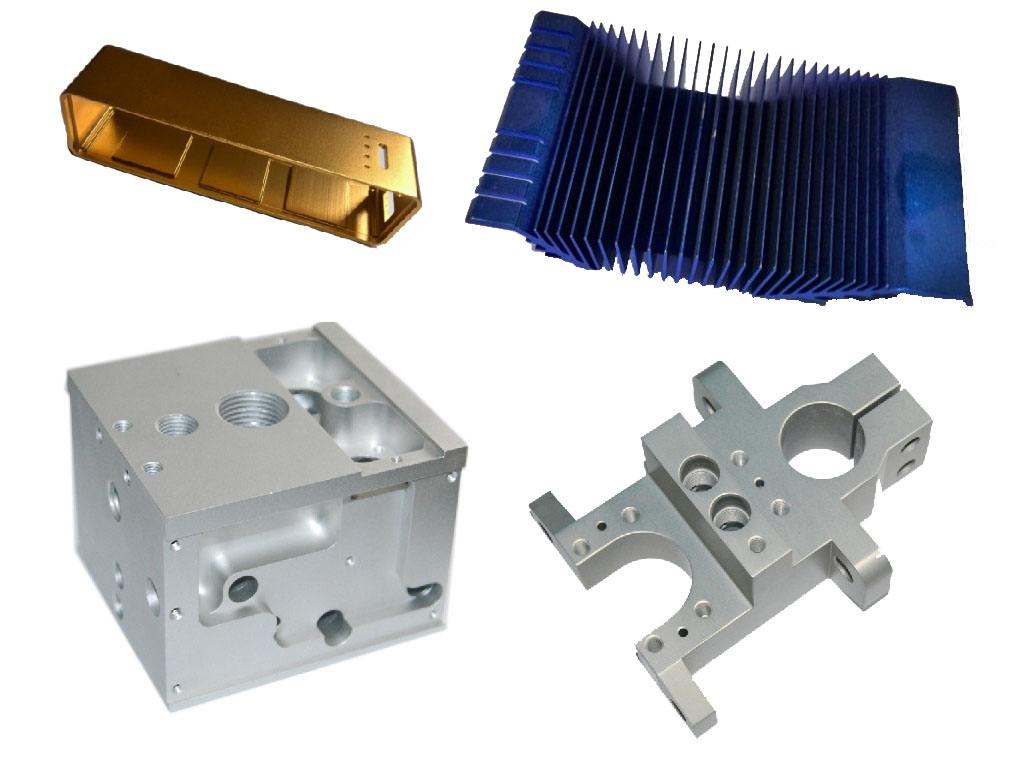

Shenzhen Novo Platinum Chi-technology professionals engaged in metal surface treatment aluminum oxide processing plant aluminum and aluminum anodizing, sandblasting oxidation, drawing oxidation, polishing oxidation, hard oxidation, and a variety of coloring, black iron plating Zinc, copper, nickel, chrome and decorative chrome, ordinary vacuum heat treatment and other metal surface treatment.

Main processing products: anodizing of machine and equipment accessories, conductive oxidation of chassis cabinets, mobile hard disk boxes, MP3, MP4, U disk shell, camera shell, cell phone case, power box shell, signs, lamp cup, lampshade, LED shell, heat sink All kinds of aluminum and other surface treatment and oxidation coloring. The company re-quality, keep credibility, customer satisfaction for the purpose, adhere to a mature sense of accomplishment for customers to make satisfactory products. We pick up the whole day car service, welcome incoming calls processing.